5 Important Traits in a CNC Machining Partner

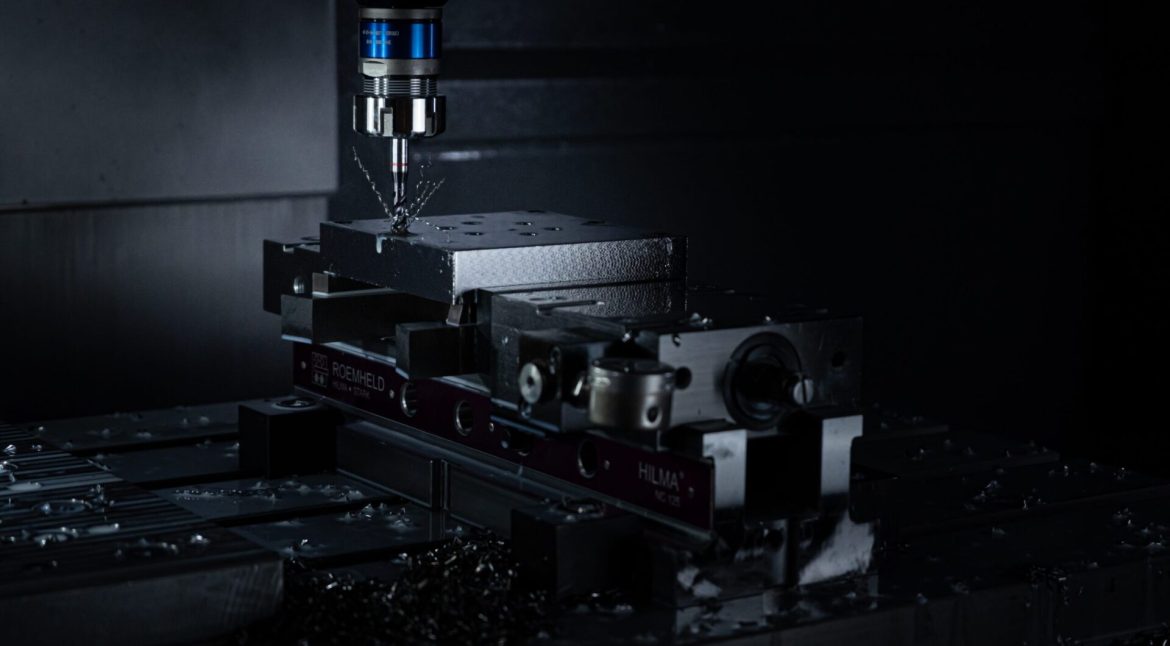

CNC machining is amazingly diverse and critical to various industries but finding the right CNC machining partner can be challenging. Before venturing into a project, whether big or small, it may be wise to invest a bit of time to ensure you are entrusting your parts to an appropriate vendor. You want your fabrication partners to be experienced, efficient, reliable, and excellent communicators. However, you first need to understand what type of services you require. Here are the 5 Important Traits in a CNC Machining Partner

For instance, do you require the fabrication of complicated multi-axis parts or simpler parts? If so, what type of material are your parts and components? Also, what size parts and types of tolerances do you need? How quick a turnaround time and what quantities will you require? Is this an R&D project that requires input from the vendor? Is this a repeat job where you need a vendor with more automation? Better understanding your needs may help you determine what questions to ask and what type of shop to seek.

1. Experience

Although nothing can guarantee a perfect fit, there is no substitute for experience and expertise. The right CNC machine shop will have lived through and overcome various issues associated with the types of parts you need to be fabricated to include material type, tolerances, size, quantities, finish requirements, assembly, etc. An experienced fabrication partner will warn you of potential pitfalls and may make suggestions to mitigate risks and improve outcomes.

2. Efficiency

Efficient machine shops will have the equipment and technology needed to fabricate your parts with accuracy, for example, consistency in quality and cost-effective steps. However, depending on the parts you are seeking to have fabricated, do not hesitate to ask how the CNC service provider will fabricate your parts. What approach will be taken? Why? What machines will be used? How will the parts be inspected? Process efficiencies will translate into consistency in quality, lead time, and long-term cost benefits.

3. Production Capacity

Perhaps more important than the number of machines, what type of machines are available to fabricate your parts? If you need simple parts (minimal features, looser tolerances) then you may not require a shop specializing in robotics and automation. Is the shop able to scale and bring your parts from successful First Article fabrication to fabrication of hundreds or thousands or parts per month over a short period of time?

4. Flexibility & Responsiveness

Things happen through the design and fabrication process. How willing and able is your fabrication partner to pivot and respond? Are you being provided with the updates you need and the input you may require to mitigate risks? Confirm what you expect from your fabrication partner, for instance, if things don’t go as planned.

5. Cost of CNC Machining

Because R&D, as well as low quantity fabrication of precision parts, is not cheap, significant costs are incurred with engineers, programmers, Quality personnel, and planners getting involved in processes before any material is placed in a machine. Therefore spending a bit more with an experienced fabrication partner for R&D projects will save you a lot of time and heartache. However, once your design, materials, and finishes are confirmed, then you need to seek fabrication partners with the automation necessary to minimize costs and maximize quality.

Contact us for a free consultation. Ricaurte Precision Inc. (www.ricaurteprecision.com) has been a trusted partner to world-leading aerospace, defense, and FDA-regulated manufacturers for over 30 years.