Highly technical industries, such as aerospace, defense, medical, and energy, demand strict tolerances for mission-critical parts. Swiss screw machines are renowned for their unparalleled precision and speed. They produce small, complex parts with minimal waste to meet the exacting requirements of those industries.

Ricaurte Precision Inc. has decades of experience combining state-of-the art equipment with advanced software to offer a range of Swiss screw machine services, making us an ideal partner for any company requiring this type of work.

The Benefits of Swiss Screw Machine Services

Swiss screw machines can handle the complex geometries of small, intricate components up to a 0.750” diameter. They can mill, turn, thread, drill, and saw while maintaining consistent, tight tolerances (+/-0.0002”) with minimal waste. The 12’ automated bar-feeder systems, designed to allow for unattended, “lights-out” operation 24/7, ensure continuous, efficient production.

Digital technology plays a vital role in every aspect of precision machining at RPI, and our Swiss screw machines are no exception. Fully automated processes dramatically increase accuracy, speed, and volume, while the closed, compact machining space delivers more precise cuts and reduced error rates. Swiss screw machines produce consistent, high-quality, complex parts at incredible speed, which sets them apart from traditional machining methods.

Versatile material capability

Swiss screw machines can produce high-precision components from a wide range of materials and cater to the diverse needs and stringent requirements of specialized industries. They can machine parts from almost any material, including exotic metals and alloys, like molybdenum, stainless steel, and titanium and plastics, including acrylic, nylon, and polycarbonate.

RPI’s Swiss Screw Machine Services

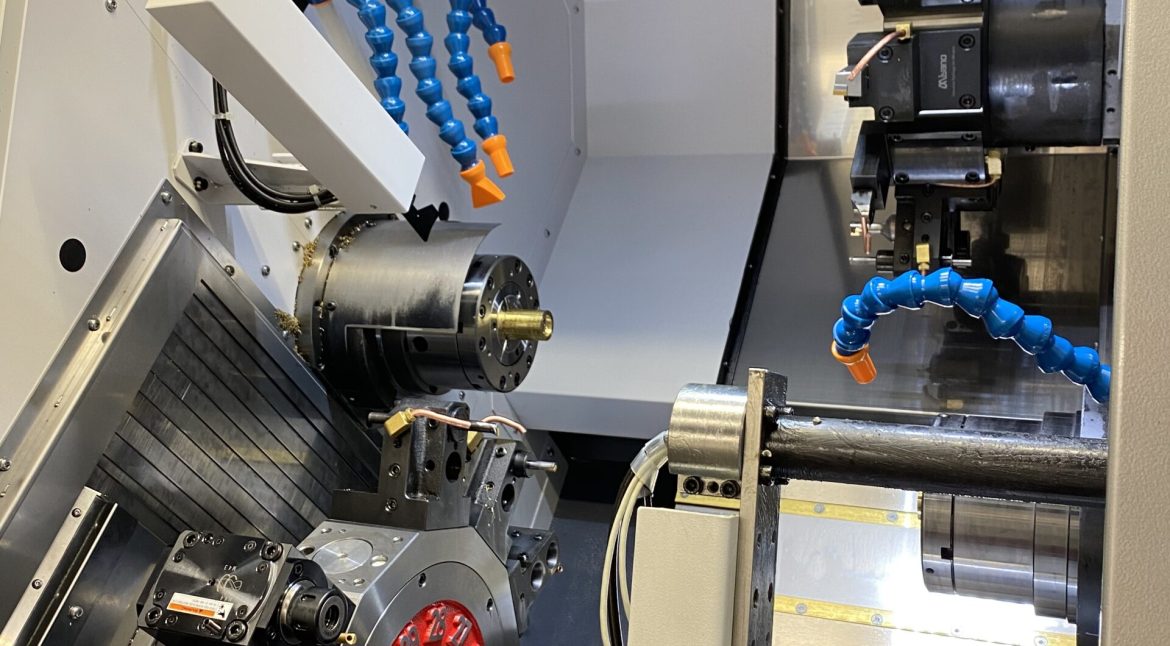

Not all precision machining companies provide Swiss screw machine services, but here at RPI, we have two types of multi-axis Swiss screw machines. These systems allow us to meet our customers’ different needs regarding component size, production speed, and volume. Here’s a brief overview of two different types of Swiss screw machines in our shop.

Citizen Cincom 5M8

The seven-axis Citizen Cincom 5M8 machines small parts up to 0.750” in diameter. It has a capacity for up to nine drilling tools, five turning tools, and 10 turret stations. A 12’ automated bar-feeder system enables us to run the machine unattended 24/7.

Miyano BNE-51

The Miyano BNE-51 features twin 12-station turrets, and it can machine small parts up to 2” in diameter. The twin turrets allow the machine to complete two cutting operations simultaneously. This system offers simultaneous three-tool machining, which significantly increases precision and production speed.

Advanced software

Excellent Swiss screw machine services demand outstanding equipment and software. At RPI, we invest in advanced, state-of-the-art software that helps us use the equipment to its full potential. We use Esprit programming software, which is well suited for multi-axis systems, including Swiss screw machines like our Citizen Cincom 5M8 and the twin turret Miyano BNE-51.

Expert Swiss Screw Machine Services

RPI integrated Swiss screw machines into the shop back in 2008. Our Swiss screw machine services come with more than 15 years of expertise and a high level of technical sophistication. We maintain a clean, extremely well-organized environment, which is essential when working with small parts.

What does all this mean from a customer perspective? RPI’s Swiss screw machine services deliver highly complex parts quickly with consistent quality and unparalleled precision. Request a quote today and discover how we can help you succeed.