Poor quality. Scrapped parts. Long manufacturing lead times. These are just a few of the problems customers encounter when their precision machining partner doesn’t use the right machine tooling for the job.

With over 35 years of precision machining experience, Ricaurte Precision appreciates the importance of machine tooling. We plan ahead and invest in premium tooling—including carbide cutting tools, ceramic machining tools, and coolant-through tooling —to complete even the most challenging jobs quickly and accurately.

RPI’s Machine Tooling Experts

To get a precision machining job done right the first time, machinists must first understand the material they’re cutting, the tolerances they need to hold, and the angles they need to achieve so that they can select the right tool for the job.

Are we removing a significant or a small amount of material? Are there tiny holes in the design that are difficult to machine with standard tooling? Are we machining plastic, steel, or an exceptionally hard material like Inconel?

The answers to these and other questions inform our decisions about the type of tool we select for each job. RPI’s highly skilled team of machinists takes the time to assess each project to determine the best tooling option before moving forward with the machining process.

RPI’s Unique Machine Tooling Capabilities

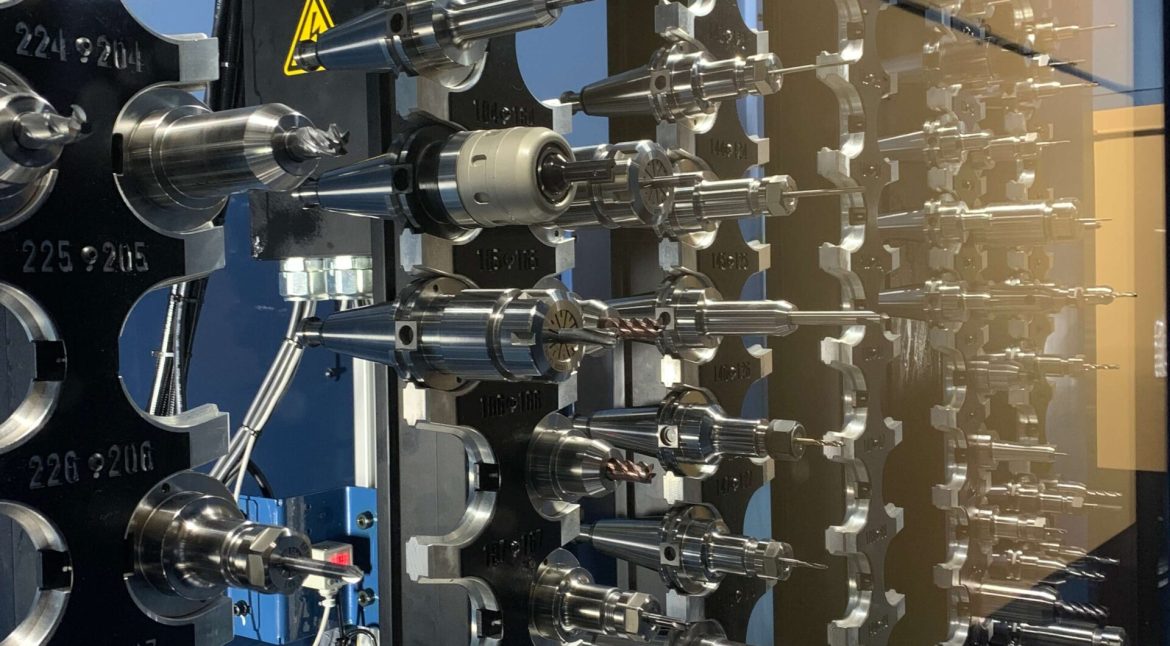

Over the years, RPI has acquired a suite of high-end machine tooling, including carbide cutting tools, ceramic machining tools, and coolant-through tools.

Not every project requires these advanced tools. But having them within arm’s reach allows our team to take on any and all tight tolerance or exotic alloy projects that come our way.

1. Carbide tooling

Carbide inserts are common in complex precision machining projects. These hard, resilient tools offer exceptional performance at a lower price point than other higher-end tooling options.

2. Ceramic tooling

Though much more expensive than carbide tooling, ceramic cutting tools are an excellent choice when we need to remove significant material from an Inconel workpiece, create tight angles, or drill small holes with a high degree of precision.

The primary challenge of using ceramic cutting tools is contending with their brittleness. Machinists must take special care to ensure they don’t cut so hard and fast that the tool breaks.

3. Coolant-through tooling

Coolant-through tooling is only available with modern CNC machines, like the ones in RPI’s shop. This type of tooling supplies coolant from the tool post to the tool edge to extend the life of the tool and enable a stable machining environment. Other benefits of coolant-through tooling include improved chip evacuation, reduced cutting temperatures, and enhanced lubrication.

RPI often uses a combination of advanced tooling. For example, we might use ceramic cutting tools to make a rough cut of a part and then use a carbide insert for the finishing work.

Choose RPI for High-Quality Tooling

When you choose RPI for your complex precision machining projects, you choose a shop with the deep expertise and technology required for your project.

Maintaining an extensive inventory of ceramic, carbide, and coolant-through tooling enables us to get projects off the ground quickly. Of course, the quality of our tooling would be meaningless without our machinists’ skills and tooling expertise, which allow us to leverage the full potential of these tools to deliver exceptional results to customers.

Stop by to meet the team and check out our equipment. We are proud of our shop and would love to show you around and answer your questions. If you’re not local, we can easily set up a virtual tour.

Request a quote to work with our expert team today!