If there’s one thing all manufacturing customers have in common, it’s the desire to get their CNC machined parts as quickly as possible. At Ricaurte Precision, fast turnaround is a priority for us, too. One of the best ways to expedite your project is to supply us with thorough, accurate part files.

Essential Part Files in Precision Machining

2D drawings and 3D models are the two part files necessary to build accurate, functional CNC machined parts.

When it comes to sending your manufacturer information, more is usually better. It isn’t enough to send only a 2D drawing or a 3D model. Each one serves a distinct purpose and contains crucial information:

- The 3D model allows us to quote parts and program machines efficiently. Dimensions that may be difficult to capture in 2D form can be expressed and manipulated in a 3D model.

- The 2D drawing provides us with critical specifications, including tolerance and surface finish requirements, masking instructions, and information on secondary operations such as plating.

How a Shop Uses Your Part Files

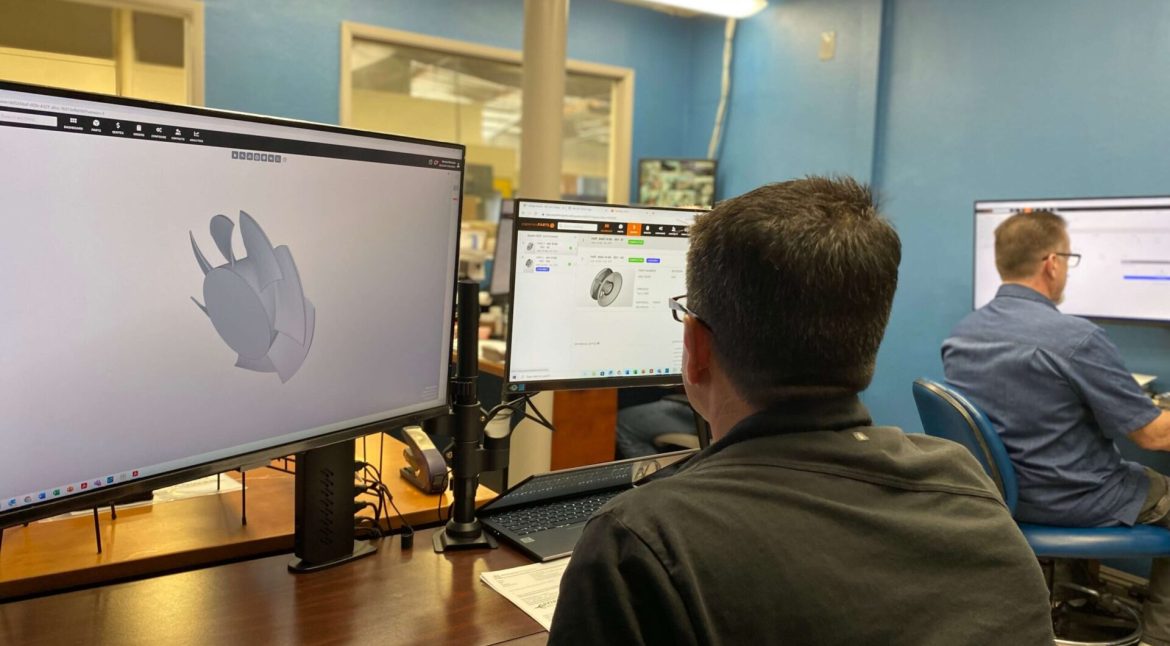

Precision machine shops refer to part files during multiple phases of a project’s life cycle. In the initial quoting and planning stages, we use part files to generate fast and accurate quotes and develop an efficient manufacturing plan optimized for cost and lead time.

During manufacturing, we rely on part files to help us program machines and verify specifications. Part files are also used to communicate design iterations that may take place during the project, so it’s crucial that 2D drawings and 3D models are always aligned with each other and up to date with the latest revisions.

What happens when precision machine shops don’t have suitable part files to work with? A lack of proper documentation can result in inefficiencies: shops might have to hastily purchase tooling, leave machines sitting idle, or take unnecessary extra steps. These seemingly minor inconveniences add cost and time to your project.

At Ricaurte Precision, we prioritize quality, and we’ll always check with customers if we’re missing key information in their part files. However, sending us sufficient information up front minimizes back and forth and helps your project move along smoothly.

How Ricaurte Precision Protects Your Part Files

If you’re worried about data security, allow us to allay your fears. We’re ITAR registered and AS9100D and ISO 9001:2015 certified. Our quoting process is fully digitized—the highly secure online quoting platform protects customers’ sensitive information while facilitating fast and accurate quotes.

When you upload your files, our client solutions team organizes the documentation so it can be digitally reviewed by our programming, purchasing, quality assurance, and production teams. Your data remains safe the entire time.

If you have any questions about creating part files, reach out to our precision machine shop! We’re happy to provide our insights ahead of time. Ready to request a quote? Submit your project details and part files, and we’ll get back to you within 24 hours.